Interviewer: Public Relations Office

For this edition, we interviewed Professor NONAKA Hiroshi of the Sustainable Resources Sciences Department of the Graduate School of Bioresources.

-Professor, what is your area of specialization?

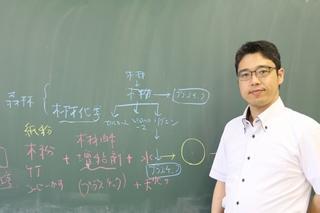

NONAKA:I am conducting research into the use of wood fibers and wood components in the Lignocellulose Laboratory of the Forest Resources and the Environment course (the faculty is Course of Forest Resources and Environmental Science). In the present day, wood is used for things like wooden posts, as the raw material for paper, and for plywood. A great deal of wood is used for these kinds of purposes and it does not have much added value. Not much wood is being sold, so the forestry businesses are having a difficult time. In our laboratory, our research is based on the idea that, by extracting the useful components of wood and giving high added value to wood powder, which normally does not have much value, we may be able to solve that problem. In particular, I am focusing on not just the use of certain components extracted from wood, but all of the components.

After doing research that involved dividing up the components of wood into detailed categories and changing and treating them over and over until we ended up with a plastic-like product (this is important research, so it is still ongoing), I thought that perhaps we could create the same kind of plastic-like product just be solidifying the wood powder in its usual state. If we want to replace the plastic products in our world, in all their complex shapes and forms, with wood and paper, we will have to revolutionize how they are made. I wanted to create wood- and paper-based materials that could be used to mass-produce products in the same way that petroleum-derived plastics are used, so I started research into creating an alternative to plastic from wood and paper.

-What kind of straw is the wood drinking straw that won the Wood Design Award last year?

NONAKA:It is a drinking straw that has been formed from a clay-like material made by mixing wood powder with a thickener (wood-derived) and water. When I say "clay-like," of course, the components are different, but you could picture it as being akin to paper clay. As well as wood powder, you could make the same kind of thing with other materials such as coffee grounds and bamboo powder. The wood powder clay that I make is both soft enough to form even the finest details when applied pressure into the tightest corners of a mold and hard enough to retain its shape when extruded, a bit like Tokoroten (agar-agar noodles). When it dries, this wood powder clay forms the desired shape perfectly. Then, if you soak that perfectly shaped object in water for a while, it will lose its shape and it can then be formed into a different shape. You could say it is the ultimate recyclable material. Even if my wood drinking straws were to flow out into the ocean, they would soon be broken down into wood powder, which would eventually rot through the action of micro-organisms, and be converted into carbon dioxide and water. However, given their purpose of use as a drinking straw, they need to be able to resist water to a certain extent. Right now, we could coat them with a petroleum-derived, water-resistant varnish and they would be usable as straws, but I want to make them completely from naturally derived materials. Instead of using petroleum-derived varnish, I want to make the straws water-resistant with naturally derived substances, such as lignin (a component that accounts for a third of wood), for example, or lacquer or sunflower oil. I am currently researching other ways of adding water resistance, but I can't yet reveal anything about that.

-Would adding water resistance mean that it would not break down completely?

NONAKA:Making something resistant to water during use does make it more difficult to break down out in the environment. However, even with paper that has a glossy surface and has been treated so water doesn't penetrate, if it is soaked in water and agitated with some kind of mixer, the fibers in the paper will break down. From a recycling perspective, paper is a highly recyclable product. In the same way, even if we make our wood drinking straws water-resistant to a certain extent, they should break down by being buffeted by the waves and crashing up against the rocks. However, they probably would not break down easily if they were just floating in the sea.

- How did your research and development of the wood drinking straw come about?

NONAKA:The main impetus came when The Pack Corporation, a packaging company that mainly deals in paper bags, proposed doing joint research with them. The Pack wanted to make their paper bag components entirely out of "paper," so we started working on the development of wood and paper materials to make the handles for paper bags, instead of plastic. That was the beginning. There are already paper cords and other materials used for that purpose, but we created handles with a more premium feel that could be used in department stores, using wood powder clay.

Wood powder clay can be formed into many different shapes, so to expand the sales channels, we also had containers, bottles, and other products made. While all that was going on, society started focusing on the problem of plastic straw waste so at Mie University, we used extrusion-forming to develop a straw made out of wood. Our wood drinking straw gained attention because of the Wood Design Award, which I think has allowed us to promote the possibilities for wood powder clay.

-What are your goals for the future?

NONAKA:I want to replace all the plastic products out in the world with products made from paper and wood. We don't know when we will no longer be able to use petroleum, which is used to make plastics. I want to be able to form a variety of usable objects, from simple items to more complex shapes, with paper and wood. Just because they can be broken down in the oceans, it does not mean they should be casually thrown away. Wood is also a precious resource, so it will be important to recover those products and turn them back into resources.

About the Researcher

Department of Sustainable Resource Sciences, Graduate School of Bioresources

Professor NONAKA Hiroshi

Development of new lignins

Three-dimensional forming of biomass powder and fibers

Use of lignocellulosic nanofibers

Addition of cellulosic materials into ceramic materials and steel slag

Development of functions through the semi-carbonization and carbonization of wood

[References]

Faculty of Bioresources website https://www.bio.mie-u.ac.jp/en/

Laboratory website https://www.bio.mie-u.ac.jp/kankyo/shinrin/lab5/index.html